- Sinomet

- Foshan, Guangdong

- 15~30 Days

- 40 HQ per month

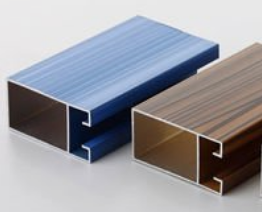

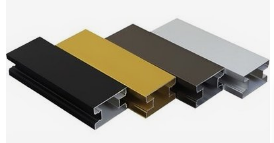

Thermal Break Aluminum Profile is designed to provide excellent thermal insulation by creating a barrier between the interior and exterior of a building. The profile features a polyamide thermal barrier that is placed between the aluminum extrusions, which helps to prevent heat transfer, making it an ideal choice for energy-efficient construction. The thermal break also helps to reduce condensation, which can lead to mold and other moisture-related problems.

Thermal Break Aluminum Profile is made up of several components, including: 1. Aluminum extrusions: These are the main structural components of the profile and are made from high-quality aluminum alloys that are strong, lightweight, and corrosion-resistant. 2. Polyamide thermal barrier: This is a polymer material that is placed between the aluminum extrusions to create a thermal break. The thermal barrier helps to prevent heat transfer between the interior and exterior of a building, providing better insulation and energy efficiency. 3. Corner keys: These are used to connect the aluminum extrusions at the corners of the profile, providing structural support and ensuring that the profile is stable and secure. 4. Gaskets: These are used to seal the gaps between the aluminum extrusions and prevent water and air infiltration. 5. Fasteners: These are used to secure the profile to the building frame and are typically made from stainless steel or other corrosion-resistant materials. Overall, the combination of these components provides a highly durable and energy-efficient building material that is ideal for a wide range of applications, from windows and doors to curtain walls and other architectural features.

We're factory.Production,sales and transportation intergration....more